Green Cotton

Reenergising Regional Australia

175K

SOLAR PANELS INSTALLED

73+

TOTAL DC MW INSTALLED CAPACITY ACROSS PROJECTS

30+

MWH OF BATTERY CAPACITY INSTALLED

Meralli Solar is Australian owned, regionally focused, with the lowest CAPEX, OPEX and LCOE at utility scale, and the lowest embedded CO2 footprint.

- The Jurchen Tech PEG Framing System allows for a high quality build, in a fraction of the time of other construction methods (fixed array, tracking etc)

- The use of a fixed tilt substructure (either east/west or north/south) depending on location) reduces supply, transportation and installation cost

- The PEG Framing System, which features close fitting arrays, allows for over twice the capacity of other systems

- Ultra low profile, just 80cm above the ground, blends in with surrounding environment

- Our unique installation process, using light and easily manageable components, means minimal use of heavy equipment on site during construction

- Installation does not require a large or specialised workforce so labour, where available, is sourced from the local community at the build site, keeping money in local communities

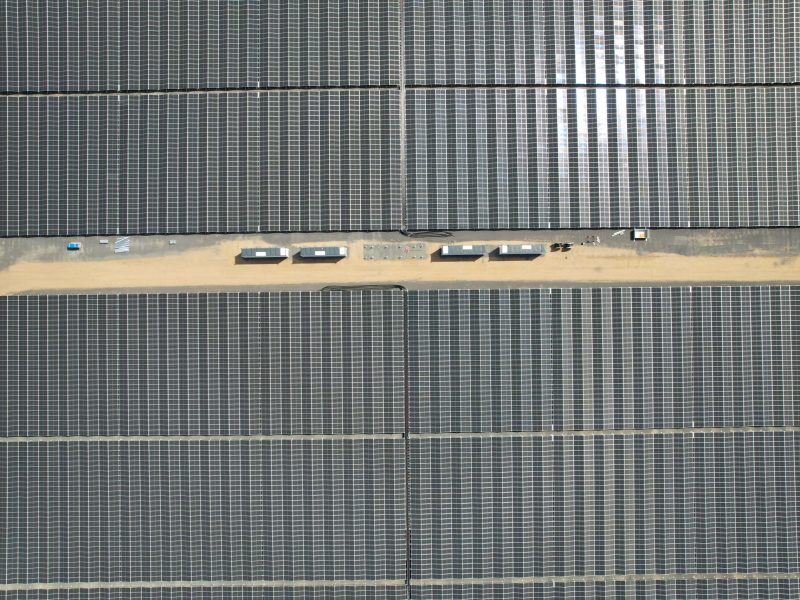

Wathagar Solar Farm

The Wathagar Solar Farm represents an exciting new model in Australian agriculture, aiming to produce clean green cotton in the long term. Located 32km west of Moree, NSW, Wathagar Stage 1 powers the cotton gin with its produced energy, exporting excess power not required by the gin.

Sustainability Goals

Sundown Pastoral Co’s commitment to reducing its on-farm CO2 footprint made the construction of this solar farm a logical next step. The array supplies energy to the cotton gin, covering up to 75% of its requirements through daytime production and battery storage. Additionally, when energy demand is low or market prices are high, the operator can export up to 3.3MW to the National Energy Market, maximising revenue.

Design and

Technology

The Wathagar Solar Farm utilises the PEG EW substructure with corner-mounted JA Solar 460W modules. The design features minimal DC field trenching, with most cable management above ground for ease of maintenance. The PEG structures are rammed 0.7m below the surface, with short PEGs set at 0.75m and long PEGs at 1.047m, allowing for easy access beneath the array for maintenance and vegetation management.

Construction and Logistics

Construction of the Wathagar Solar Farm spanned 12 weeks, spread over several months due to significant flooding that impacted site accessibility and interstate deliveries. Despite these challenges, the build proceeded smoothly on the highly reactive black soil, which can be problematic for other framing systems. Four 30-tonne battery units were installed with the assistance of two Muggleton’s cranes, alongside a Sungrow central inverter.

Energy Production and Economic Impact

The array produces approximately 30 MWh per day, covering up to 75% of the energy needs for the 24-hour ginning operations. During periods of high energy prices, the owner can halt gin operations to export energy to the grid, benefiting both financially and contributing to grid stability. This project marks the second Meralli build to support dispatchable energy for the NSW medium voltage network.

Environmental

Benefits

The Wathagar Solar Farm reduces CO2 emissions by 9,874 tonnes annually and is projected to decrease total CO2 by 296,220 tonnes over 30 years. This demonstrates the viability of renewable energy in large-scale agricultural operations, where energy consumption and cost are critical issues. Occupying less than 6 hectares, the array supports an annual throughput of more than 200,000 bales of cotton.

Community and Economic Contributions

During construction, the project created eight jobs, with staff accommodated locally. Local subcontractors were engaged for installation and commissioning, injecting an additional $300,000 to $400,000 into the local economy. The solar farm has created continuing local employment for the operations and maintenance phase of its life cycle. Meralli also sponsored the Moree Boars’ scoreboard for two years, fostering community relations.

Construction Challenges and Solutions

The extremely wet conditions during construction highlighted the importance of proper civil preparation, allowing the project to proceed despite adverse weather. Structural integrity was enhanced by installing additional rods at the perimeter of each block, increasing rigidity in high winds. Regular PV panel cleaning is anticipated due to cotton dust and prevailing wind conditions . This will be completed using a robotic, electric-powered, cleaner accredited for PEG EW use.

The Wathagar Solar Farm is a breakthrough project for Australian agriculture, demonstrating that energy costs can be significantly reduced while establishing a cash-flow-positive asset and reducing CO2 emissions. This win-win-win model sets a precedent for future sustainable agricultural practices.

Connect With Us

DR METHUEN MORGAN

CEO

Executive Director

+61 429 192 087

DAVID MAILLER

Executive Director

(Construction)

+61 487 765 229

ED CAMPBELL

Director

(Business Development)

+61 488 277 421