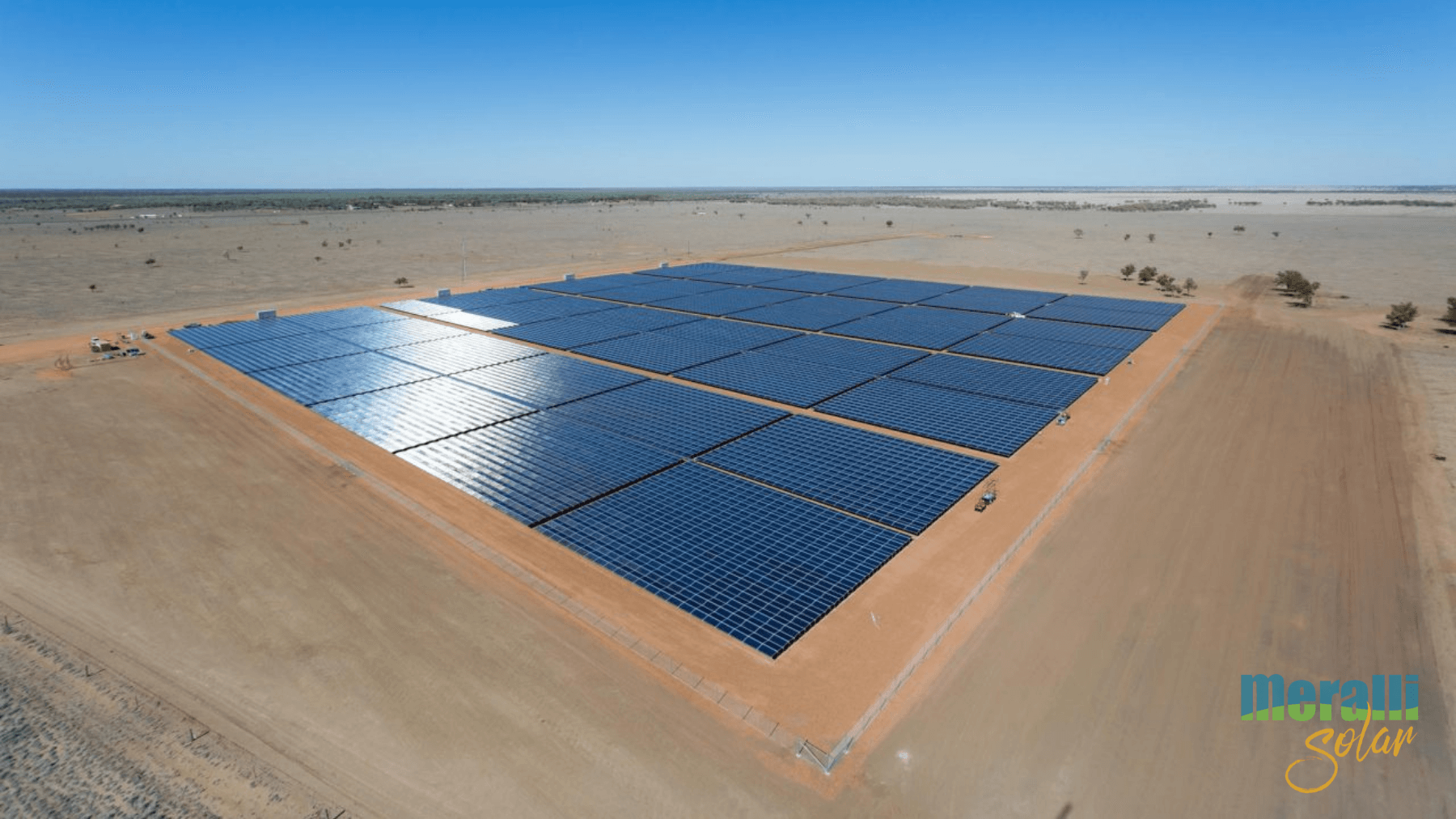

Dunblane

Completed: 2018

Size: 11 MW DC

Purpose: Generator

Location: Barcaldine, Qld

The 11MW Dunblane project in Barcaldine, Queensland is the largest, privately funded, unsubsidised solar farm of its type currently in the world and was built in just 10 weeks and 4 days; achieved without any tax payer subsidies and using an Australian workforce.

The Jurchen Technology PEG system allows for a fast, high-quality build in a fraction of the time compared to other methods. Further, this system presents a low workplace health and safety risk, with minimal heavy equipment onsite, no install operations above shoulder height, and no 240-electrical equipment used. Component parts such as pegs and plates are light and manageable, and the modules are comfortably handled by two people. The main workplace health and safety risk with this system are blisters, sunburn and dehydration.

Pegging trailers installed a minimum 480 pegs per day; solar panels moduling rates as high as 1700 per day. The PEG frame system installation costs achieved were approximately 13 cents a watt, excluding electrical work connection costs and frame and moduling costs.

Local workers creating local energy – it’s a no brainer – Cam Mace, Barcaldine

The system doesn’t require a large or specialised workforce. Initially a team of nine was required for the marking and pegging phase. increasing to 21 for the moduling phase. Casual team members were hired predominantly from the local community and Meralli also provided work opportunities for young, disadvantaged people on this project.

Meralli ensured that Barcaldine businesses benefited with all possible consumables purchased locally.

What the locals said

They were terrific customers. They were always friendly, always happy. They remembered names. They were very complimentary of the meals they had. They were very appreciative of anything extra we did for them. And we loved having them here. When they go into a town they try to support everyone. They try to spread their money around. They were just terrific support for the town. They were exceptional guests. I would recommend them to anyone.

They came and introduced themselves when they arrived. Couldn’t have been more helpful and more approachable. They were very friendly, got along well with the public. And I think they fitted in well with the community. And they’ve built some good friendships. When they came to town they approached us to find out what we had in stock, and what was available to them. They didn’t just expect to bring everything in and not to support the locals. They have tried to buy local where they could.

Meralli were very good to deal with. We had a 3 month contract to provide breakfast, morning tea and lunch each day. Their communication with us as a business was great. They were upfront, let you know what they wanted and gave feedback, which is great when you are in business. Dave and Methuen were very community minded and came to town and invested in the community.

I was commissioned by Meralli Solar to capture construction of the Dunblane Solar project from start to finish. They were all very easy to deal with, professional, practical and went out of their way to support the local businesses. They understand regional businesses and are obviously passionate about regional economies. It was very rewarding to work with a company who has such big goals whilst having their feet on the ground.

We provided steel fabrication, modified steel components & supplied steel fencing to Meralli Solar during construction of their Dunblane Project in Barcaldine. They were easy to deal with, efficient, organised and paid on time, which is great for a small business. We appreciated their business and that they went out of their way to support local businesses in Barcaldine. We would recommend any small business to work with Meralli, no hesitation.

“When David and Methuen from Meralli Solar came to Barcaldine, they were so enthusiastic about not only their project, but how they could fit in with our community and kick a few goals for us. They contributed to our festival and other community projects, shopped locally, sourcing as much of their materials as they possibly could. They were very community minded.”

read more

The Greenfields Site. The Dunblane Solar Farm is located 2.5 km North West of Barcaldine on the Barcadine-Aramac Rd.

The Greenfields Site. The Dunblane Solar Farm is located 2.5 km North West of Barcaldine on the Barcadine-Aramac Rd.

The next step was to lay a 50mm gravel base to seal the surface of the array. Once it is rolled and packed it provides a hard surface for line marketing. It helps fill in any cracks which provides a solid structure which into which the pegs can be driven. It suppresses the dust that would inevitably settle onto the panels during construction and production. And because it is permeable it traps any moisture in the soil, reducing any potential movement in reactive or even highly reactive soil. Prior to the base being laid a residual herbicide is applied to the site. This together with the compact ability of the base suppresses the growth of weeds and grasses under the array. While it does not eliminate the need for spraying it does significantly reduce the onsite maintenance.

The next step was to lay a 50mm gravel base to seal the surface of the array. Once it is rolled and packed it provides a hard surface for line marketing. It helps fill in any cracks which provides a solid structure which into which the pegs can be driven. It suppresses the dust that would inevitably settle onto the panels during construction and production. And because it is permeable it traps any moisture in the soil, reducing any potential movement in reactive or even highly reactive soil. Prior to the base being laid a residual herbicide is applied to the site. This together with the compact ability of the base suppresses the growth of weeds and grasses under the array. While it does not eliminate the need for spraying it does significantly reduce the onsite maintenance.

Moduling up is the most labour intensive part of the operation. The panels are manually carried in – two at a time – and put in place. Modules are placed and hand tightened. The modules are checked for correct placement and then the modules are locked down into their final position.

Moduling up is the most labour intensive part of the operation. The panels are manually carried in – two at a time – and put in place. Modules are placed and hand tightened. The modules are checked for correct placement and then the modules are locked down into their final position.

A low profile, with ~90cm above ground reduces glare experienced by farm neighbours – while at the same time providing enough space to replace panels or carry out any required maintenance.

A low profile, with ~90cm above ground reduces glare experienced by farm neighbours – while at the same time providing enough space to replace panels or carry out any required maintenance. The low height of the PEG Frame System constitutes a low workplace health and safety risk. With nothing above shoulder height the risk of a serious compression injury is reduced.

The low height of the PEG Frame System constitutes a low workplace health and safety risk. With nothing above shoulder height the risk of a serious compression injury is reduced. At completion our labour force was made up of 15 workers. Throughout the install our labour force ranged from 7 up to 21 during our moduling up period.

At completion our labour force was made up of 15 workers. Throughout the install our labour force ranged from 7 up to 21 during our moduling up period.